Our Products

Latest News

NZ HortBin hits NZ shores

Click here to read more..

Viscount Plastics cleans up at the Pampito Awards

Click here to read more..

Viscount Plastics is the proud winner of the Chartered Institute of Logistics and Transport's prestigious "Safety, Security and Environmental Innovation" award for 2010.

Click here to read more...

Research & Development

Innovation

Viscount Plastics places a high priority on working with our customers to develop new and exciting plastics products. Our Design and Operations team work hand in hand with customers to assist them in either over coming a particular issue they may have, for instance maximising shelf and logistical space by using a square or rectangular container, or simply to create a new and exciting products!

Following are but a few of the exciting projects we have developed.

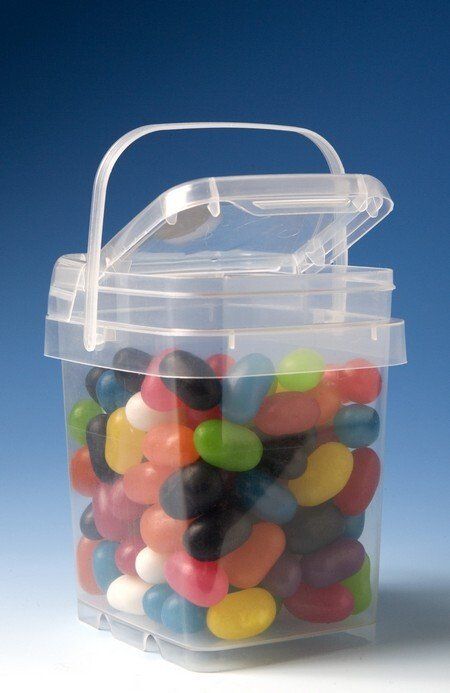

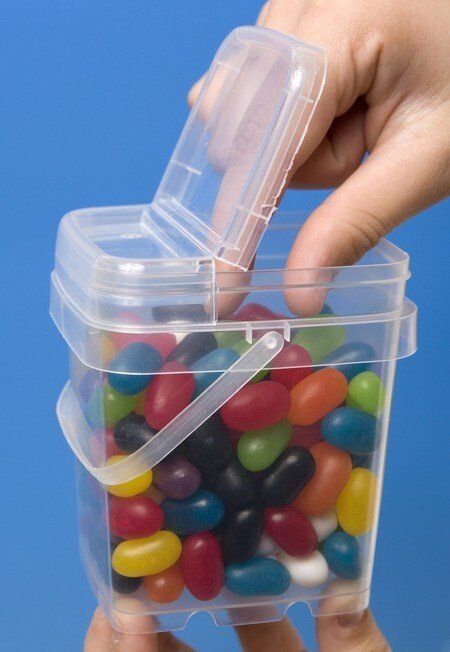

EZY Stor

The EZY Stor is a 400ml rectangular plastic container, 100% recyclable with self-hinge 'flip' type lid and featuring a tamper resistant/evident strip. The EZY Stor container was developed specifically for Viscount Plastics customer EDL Fasteners Ltd, a long-established and leading distributor of industrial, construction and universal fasteners.

The Challenge

To create brand awareness and consumer impact at hardware store point of sale, EDL initiated a repackaging programme based on introducing rectangular containers. The challenge was to develop a rectangular container to lift EDL clear of the clutter of products in traditional round screw top PET jars. Elements of the design brief included space-efficient dimensions and a lid that would give easy and comfortable access to contents. Adding to the challenge was a 'fast track' timeline.

The Innovation

Working with EDL Fasteners in a highly effective supplier-client partnership, the Viscount Plastics project team not only showed innovation in developing a lightweight but strong 400ml container but also adherence to the 'fast track' time line. Product concept drawings were approved in March 09, a prototype presented a month later, agreements signed in June and in late September tooling was commissioned. Moulding a flip lid was new territory for Viscount, but even so, full scale production has gone without a hitch since early January 2010.

Aside from delivering a wide opening lid permitting easy access, Viscount also translated the design brief into freight and shelf efficient dimensions.

These dimensions also allowed EDL Fasteners to implement highly visible colour-coded labelling that at a glance, identifies the type of screw, its corrosion protection level and common use. Other features include a convenient handle for carrying multiple packs, the EDL logo moulded into the 'flip' lid, and a clip to carry a complimentary drill bit. Innovation also extended to dispatching the EZY Stor base’s and lids to EDL. Both are delivered in Viscount Plastics Returnable Transit Packaging (RTP) products. Bases and lids are loaded into foldable bins that when emptied collapse to a fraction of their assembled height. As well as reinforcing the cost benefits of RTP, foldable bins, reflect the worldwide trend away from cardboard and single journey wooden pallets, both of which create landfill and atmospheric waste issues.

Eurotainer

3.2 litre rectangular container with non-tearing 'breakout' tamper evidence tab/lid release.

Client: Nestle New Zealand

The Challenge:

Distributing soups, stock and sauce mixes to supermarkets and restaurants in 1.2 and 1.6 litre rectangular containers imported from Germany has proven to be economically viable for Nestle New Zealand, but management knew that to introduce bulk distribution in a 3.2 litre container mirroring the family look importing a large volume container was out of the question.

The Innovation:

Not only did the Viscount Plastics design network develop a 3.2 litre container to sell alongside the 1.2 and 1.6 litre German manufactured containers, we also incorporated a number of changes specific to New Zealand requirements. One of these was a tamper evidence tab/lid release 'break out' tab that could be easily torn but did not break off to potentially fall into and contaminate contents. In designing the moulding tool we also incorporated an embossed Nestle logo into the lid.

The injection mould was manufactured in ? with production at our Auckland plant. As part of this project we also engineered a robotic arm to remove the container from the mould.

Auto Racing Floor Tile

Our primary market for this 33.3cm x 33.3cm interlocking plastic tile is the US auto racing industry where it is used as temporary flooring in pit and hospitality areas. An appreciated feature is the ease with which we can produce the tile in corporate sponsor or team colours. Right now we are making inroads into the Australian auto race industry. Hire companies are also beginning to appreciate the benefits of this tile as demountable flooring for tents, caravan awnings, etc.